Cassava — a woody shrub cultivated for its edible, starchy, tuberous root — is a major staple in Nigeria, the world’s largest producer of the crop. Drought tolerant and carbohydrate rich, cassava is a lifeline to the country’s 30 million smallholders who produce 90% of the country’s annual output of over 53 million metric tonnes. The root’s exceptionally short shelf-life means that more than 40% of this yield is lost before it is processed.

It is IDH’s goal to halve the yield loss to 20% by 2020 — and help turn a wasted crop into economic gain for the local farmers.

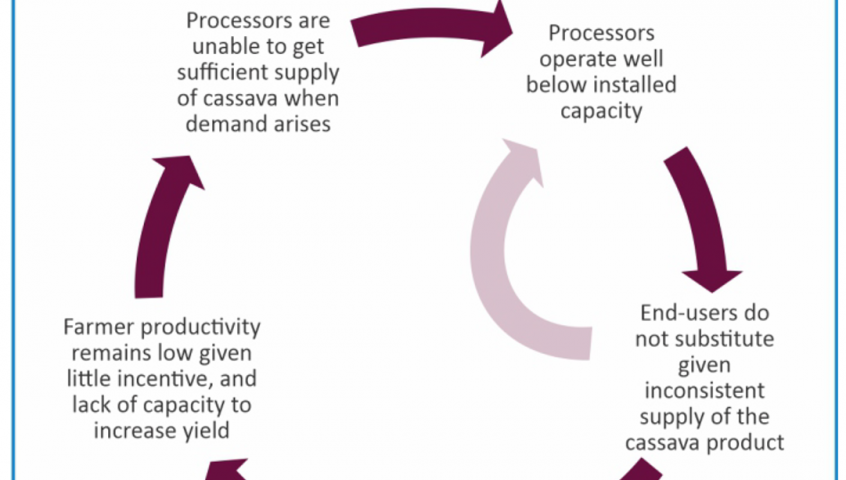

The short shelf-life of cassava, which deteriorates within 24 to 48 hours of harvesting, means the root is used primarily in food products that can be processed on or nearby smallholder farms. The post-harvest loss situation is worsened by low yields, poor handling, low on-farm processing, poor transportation infrastructure, and unorganized market structure — resulting in significant spoilage of food and economic opportunities, especially in the light of a recent upsurge in demand for cassava derivatives (including flour, starch, ethanol and syrup) by large food manufacturing companies.

Rockefeller Foundation

In support of industrializing the cassava value chain in Nigeria to optimize for yield loss reduction and improved income for smallholder farmers, Rockefeller Foundation awarded a grant of $2,000,000 to IDH.

The grant, which provides financial support for IDH’s cassava initiative in Nigeria until 31 December 2021, forms part of the Foundation’s YieldWise initiative, which seeks to promote sustainable ecosystems and reduce food losses by at least 50% in representative value chains, improving millions of rural lives — with the Nigerian cassava industry as one of the key focus areas for optimizing on loss reduction.

With the grant from Rockefeller, IDH set out to deepen industrialization in the cassava value chain in Nigeria by supporting processors to integrate smallholder farmers into their supply chain through a block farming model. Through YieldWise, IDH worked with processors on a block farming model, in which the processors acquired farmland close to the factories and contracted clusters of farmers to grow cassava on the land.

Read more in the following case studies and get inspired by the stories and results

A supported supply scheme solution

In order to raise the income and economic well-being of cassava farmers through reduction of post-harvest losses in Nigeria’s cassava value chain from 40% to 20%, IDH is providing technical assistance to cassava processors to integrate smallholders into their supply chains and resolve the systemic challenges of the value chain.

Through a scheduled and agreed supply scheme between processor and farmers, IDH is using a robust Service Delivery Model (SDM) that will cover training on best agronomical practices, supply of inputs and mechanization services. The use of post-harvest loss technology will be adopted whenever available.

By piloting the scheme in at least six projects, our goal is to demonstrate that cassava processing, with smallholder inclusion, is sustainable and can reduce post-harvest losses and lead to at least 74% increase in the income of smallholder farmers. Through a block farming system and a farmer-to-farmer intervention, the program is expected to build the capacity of at least 20,000 cassava farmers and link them to markets.

Additionally, our intervention is expected to incentivize banks and investors to tap into the ample investment potentials in the sector to bridge the huge demand gap in the cassava derivatives market in Nigeria.

Contracting partners

The contracting partners are processors that meet the funding requirements of the program.

The processor co-funds, with IDH, the inclusion of smallholders in their supply chains. Where a commercial end-buyer is part of the coalition and is making financial contribution in cash or kind, the contracting will become tripartite. So far, we have partnership arrangements with Nestle and Unilever. Other commercial end-buyers for cassava derivatives in Nigeria include Nigeria Breweries, pasta food companies, distilleries and flour mills, among others.

The processor co-funds, with IDH, the inclusion of smallholders in their supply chains. Where a commercial end-buyer is part of the coalition and is making financial contribution in cash or kind, the contracting will become tripartite. So far, we have partnership arrangements with Nestle and Unilever. Other commercial end-buyers for cassava derivatives in Nigeria include Nigeria Breweries, pasta food companies, distilleries and flour mills, among others.

Project targets and impacts

By 2020 the goal of our Cassava initiative, under the Rockefeller grant is to ensure:

- 72,000 MT of cassava is sold to processors and 126,000 MT to alternative buyers

- 20,000 farmers are aggregated to meet the quality and quantity required by processors

- 6,000 farmers are connected to mechanization, new farming technologies and input financing.

Some of the key impacts expected from the program include:

Rural and national development

With direct beneficiaries expected to double their yield and income, and indirect beneficiaries expected to record a 50% increase in yield. In Nigeria, at least 600 new jobs will be created by the projects and the steady revenue flow of over $20m per annum generated by the project and its spiral effects will have immense economic and social benefits to the affected communities. Substantial foreign exchange savings will be made annually from substitution of imported derivatives.

Diffusion of improved technology for agricultural productivity

Establishing modern farming for industrial production, with the block farms acting as incubation centers. Deployment of an efficient SDM ensures that farmers are trained on Good Agricultural Practices, modern production technologies, provided with improved planting materials, and other agro inputs.

Reduction of post-harvest losses of Cassava

Training farmers on planned and proper harvesting and handling of cassava tubers to reduce bruises, spoilage and deterioration, and ensuring processing facilities are located near farms (ideally within a 50 km radius) to reduce transportation time hampered by poor road infrastructure. The introduction of special packaging bags will also help prolong the shelf life of the roots.

Publications

| Title | Type | Year | Regions | TAF |

|---|---|---|---|---|

| Net Zero in Agriculture: Role of Technologies | Report | 2023 | - | - |

| Value chain analysis for cash crops in Southern Chad | Other publications | 2023 | Africa | Landscapes Program |

| Grains for Growth Program | Report | 2023 | Africa | - |

| The Block Farm Model: Confronting the Challenge of Supply Chain Management in Africa | Other publications | 2022 | - | - |

| IDH Cassava Program | Report | 2021 | - | - |

| Report: From Zero to Hero – Transforming the HQCF Sector in Nigeria | Report | 2021 | - | - |

No publications found.